Hinged Snap Cap

Hinged Snap Cap

| Revision | Service | Material | Quoted Duration | Actual Duration | Rating |

|---|---|---|---|---|---|

| A | Design & Print | PET-G | 7 Days | 4 Days | 5 |

| B | Design & Print | PET-G | 5 Days | 2 Days | 5 |

Buyer Request

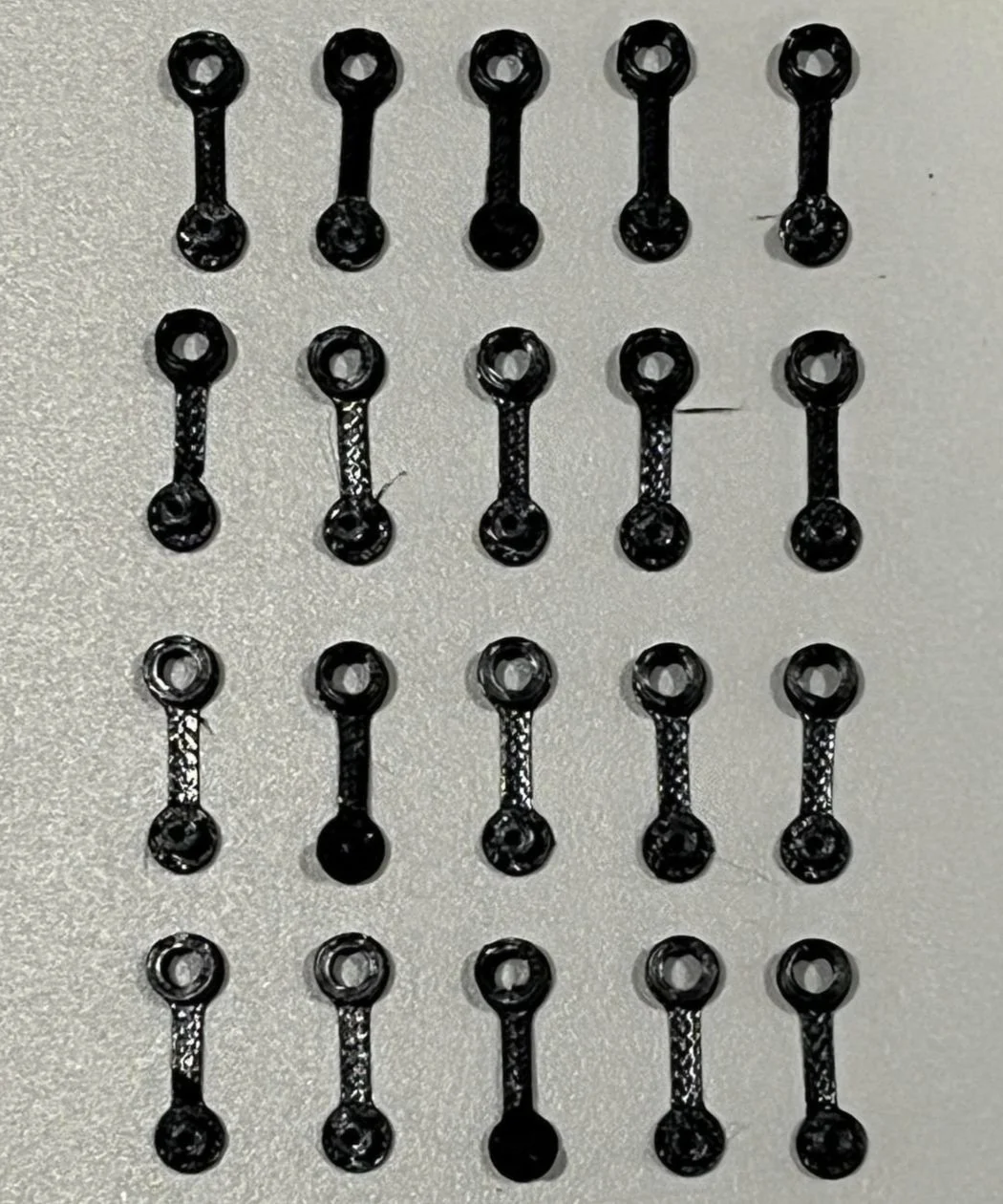

Design and print 20 screw caps with a living hinge that allows for the top diameter to snap into the bottom diameter.

In order to adhere to fairly small dimensions while maintaining print quality and integrity, pieces were designed with tight tolerances.

Small Scale 3D Printing

The biggest challenge in fabricating this part was ensuring quality while adhering to the specified dimensions.

In order to produce a reliable part at this size, PET-G was chosen instead of PLA. This allowed for greater durability and flexibility at scale which was especially important in achieving a thin, viable living hinge.

In order to reinforce the cap portion further, a base of diameter 4.7 mm was added which increased the strength and print reliability dramatically. Additionally, the holes were increased by 0.2 mm in the base and 0.1 mm cap to account for tolerance.

Fusion 360 Hinged Snap Cap Model

This project prompted me to print with PET-G for the first time. Until this point, I had only printed with PLA and the smallest part I had printed before was maybe 1.5x - 2x as large. Additionally, while I have made print in place hinges before, this was my first time designing a living hinge.

Getting the thickness of the hinge to be enough that it would still flex reliably while not being too brittle and dialing in the tolerance for the parts with PET-G made the process so much more interesting and has definitely given me a clearer perspective on the limits of my printer and my abilities.

Revision A approved for use on portfolio. Technical Drawings available at request.